PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) are both important terms in the electronics industry. Many people use them interchangeably, but they are two different things.

The main difference between PCB and PCBA is that PCB refers to bare boards, whereas PCBA refers to a completed board with all the electronic components mounted all the way around to make it work as intended. Unlike PCBs, which do not contain the required components, PCBAs are complete and functional boards. PCBs and PCBAs are two different stages of the same process; PCBAs are built on top of existing PCBs.

What Is the Definition of PCB?

PCB stands for Printed Circuit Board. It is a flat board made of non-conductive material, usually fiberglass, that houses electronic components and provides mechanical support to them. The real magic lies in the thin layer of copper foil laminated onto the surface of the board, which forms conductive pathways or tracks.

These tracks act as highways for electrical signals to travel between different components on the circuit board. They are meticulously designed using computer-aided design (CAD) software and etched onto the board through a process called PCB fabrication.

The beauty of PCBs is their versatility. They can be single-layer, double-layer, or multi-layer boards depending on their complexity. Single-layer boards have only one layer of copper tracks while double-layer boards have two layers with connections made through vias.

Moreover, PCBs come in various sizes and shapes tailored to specific applications. From simple circuits used in calculators to complex motherboards found in computers, these ingenious little boards power our modern devices effortlessly.

In essence, PCBs serve as an essential foundation for electronic components by providing connectivity and structure all within a compact package.

Types of PCBs

There are several types of PCBs available in the market, each catering to specific needs and requirements. Let’s explore some of them!

- Single-Sided PCBs: As the name suggests, these PCBs have components mounted on one side only. They are widely used in simple electronic devices like calculators and radios.

- Double-Sided PCBs: These boards have components mounted on both sides, connected by through-hole plating or surface mount technology (SMT). They offer increased circuit density and better functionality than single-sided ones.

- Multi-Layered PCBs: These advanced boards consist of multiple layers sandwiched together with insulating material in between. With more layers, they can accommodate complex circuits for high-performance applications such as smartphones and computers.

- Rigid-Flex PCBs: As a combination of rigid and flexible materials, these boards allow for bending or folding without compromising functionality. They find applications in aerospace, medical devices, and wearable technology.

- High-Frequency PCBs: Designed for transmitting signals at high frequencies with minimal signal loss or distortion, these specialized boards are commonly used in communication systems like satellites and radar equipment.

- Metal Core PCBs: With a metal core layer acting as an efficient heat sink, these boards dissipate heat effectively from power sources or LED lighting systems.

Applications of PCBs

PCBs, or printed circuit boards, are an integral part of many electronic devices that we use in our daily lives. Their versatility and compact size make them ideal for a wide range of applications.

In the realm of consumer electronics, PCBs can be found in smartphones, tablets, laptops, and televisions. They provide the necessary connections between various components to ensure smooth functioning. Without PCBs, these devices would not be able to perform their functions effectively.

PCBs are also widely used in the automotive industry. Modern vehicles, they control everything from engine management systems to entertainment systems. The compact size of PCBs allows them to fit seamlessly into tight spaces within vehicles while providing reliable connections.

Industrial applications also heavily rely on PCB technology. From manufacturing equipment control panels to power supply units in factories and plants, PCBs play a crucial role in ensuring efficient operations and automation.

The medical field benefits greatly from the use of PCBs as well. Medical equipment such as MRI machines, defibrillators, pacemakers, and even simple thermometers incorporate these boards for accurate measurements and precise control.

What Is the Definition of PCBA?

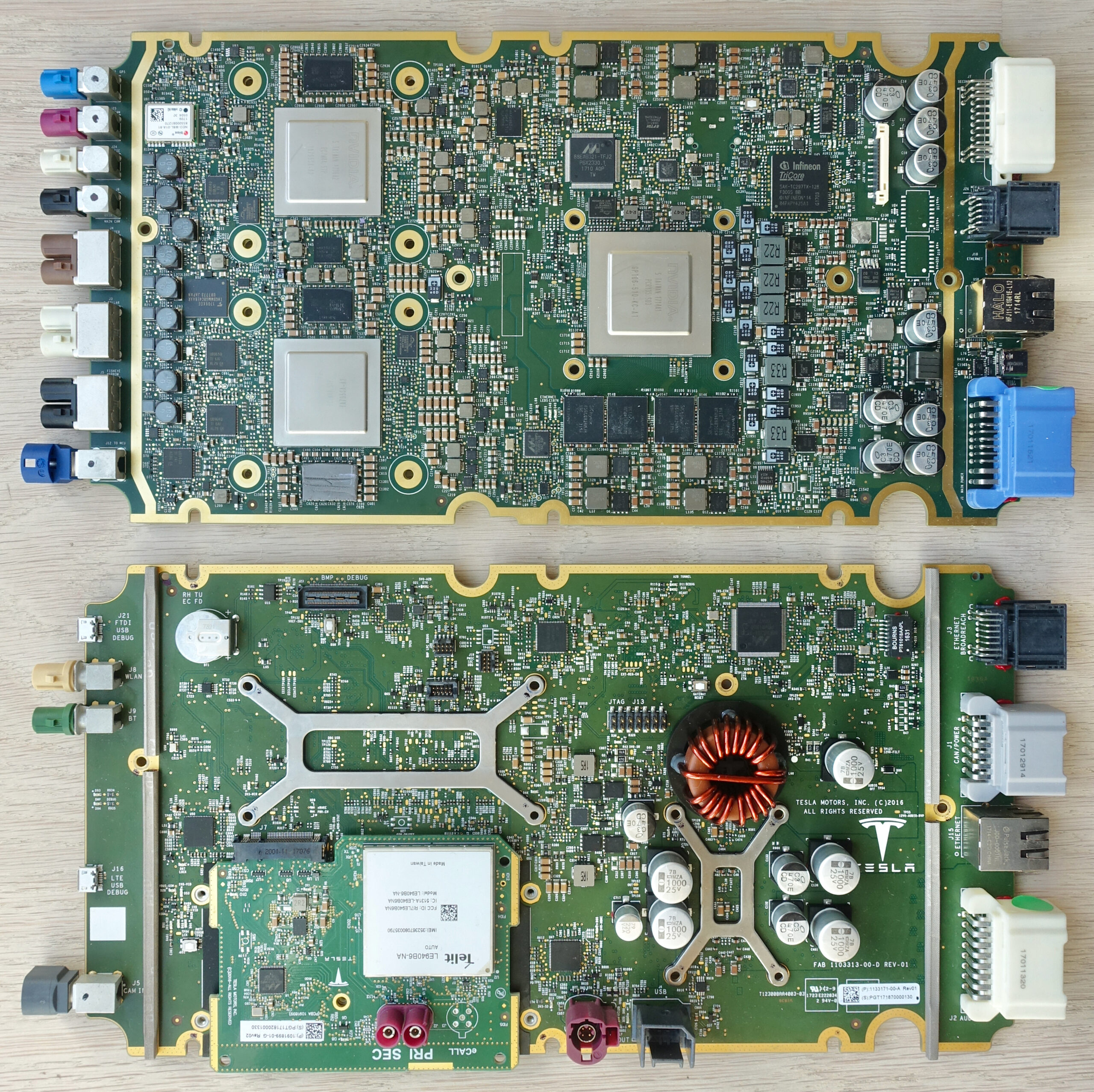

PCBA stands for Printed Circuit Board Assembly. It refers to the process of soldering electronic components onto a printed circuit board (PCB) to create a functional electronic device. In other words, PCBA is the final step in manufacturing an electronic product.

During the PCBA process, various components such as resistors, capacitors, integrated circuits, and connectors are carefully placed and soldered onto the PCB according to a specific design layout. This assembly is done using advanced machinery or sometimes even by hand depending on the complexity and volume of production.

The PCB acts as a platform that connects different electrical components together and provides mechanical support for them. The combination of these components creates an integrated circuit that enables the device to function properly. Once all the necessary components have been mounted on the PCB, it can be tested for functionality before being packaged into its final form.

PCBAs are crucial in today’s technological world as they are used in countless devices we rely on daily. From smartphones and computers to medical equipment and automotive systems, PCBA plays a vital role in bringing these products to life.

Types of PCBAs

PCBAs, or Printed Circuit Board Assemblies, are the result of mounting electronic components onto a printed circuit board.

There are various types of PCBA technologies available today, each with its own unique features and advantages.

- Through-Hole Technology (THT): This traditional PCBA technology involves inserting component leads through holes in the circuit board and soldering them in place. THT is known for its reliability and robustness, making it suitable for applications that require high mechanical strength.

- Surface Mount Technology (SMT): SMT has gained popularity due to its smaller footprint and higher assembly density compared to THT. Instead of through-hole connections, SMT components are mounted directly onto the surface of the PCB using solder paste.

- Ball Grid Array (BGA) Technology: BGA is a type of surface mount package that uses an array of tiny balls as electrical connections between the component and the PCB. This technology offers excellent thermal performance and high-speed connectivity, making it ideal for advanced digital devices like smartphones and gaming consoles.

- Chip-on-Board (COB) Technology: In COB assembly, bare semiconductor chips are directly bonded to a PCB substrate without encapsulation or packaging materials. COB provides compact size, low profile height, improved heat dissipation capabilities, and reduced interconnection impedance.

Applications of PCBAs

PCBs serve as the foundation for electronic components, providing a platform for connecting and supporting various electronic elements. They come in different types such as single-sided, double-sided, and multilayered PCBs to suit different applications.

On the other hand, PCBA takes it one step further by not only incorporating the components onto the board but also soldering them together to create a functional electronic assembly. This enables devices like smartphones, computers, medical equipment, and automotive systems to operate smoothly.

The applications of PCBAs are vast and varied. From consumer electronics like laptops and televisions to industrial machinery control systems, PCBA is at the heart of many modern technologies we rely on daily. Additionally, sectors such as healthcare benefit from advanced PCBA technology in medical imaging devices or implantable medical devices.

Both PCBs and PCBAs are essential components within the electronics industry, but they differ in terms of their purpose and functionality. Understanding these differences can help manufacturers choose the right solution for their specific needs.