How a Radar-Level Transmitter Works

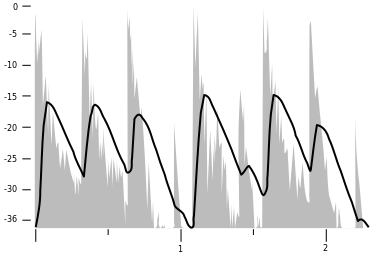

Radar level transmitters have quickly become an industry standard for measuring liquid levels in a range of applications. They operate by emitting high-frequency radar waves toward the liquid surface and then receiving the reflected signal.

These waves can penetrate material tanks, allowing for accurate level measurement even in challenging environments. The transmitter then calculates the distance between the transmitter and the liquid surface based on the time delay between the emitted and reflected signals.

This information is then transmitted to the control system for analysis and further processing. Overall, radar level transmitters are highly reliable and accurate devices that have revolutionized the liquid level measurement process.

Advantages of Using a Radar-Level Transmitter

When it comes to measuring liquid levels, the advantages of using a radar level transmitter cannot be overstated. This advanced technology offers highly accurate and reliable level measurement with the ability to work in harsh environmental conditions.

Unlike other level measurement methods, a radar level transmitter does not require direct contact with the liquid being measured, which eliminates the risk of contamination and allows for remote operation. Furthermore, radar level transmitters can be used to measure the levels of various liquids, including those with high viscosity or low dielectric constants.

With their many benefits, it’s clear that radar level transmitters are a valuable investment for any industry that requires precise liquid level measurement.

Types of Radar Level Transmitters Available

In the field of level measurement, radar transmitters have become increasingly popular due to their accuracy and reliability. With radar technology, there are different types of radar level transmitters that are available for use, each catering to specific industrial needs.

For instance, non-contact radar level transmitters are ideal for applications where there is little or no interference from the vessel or tank being measured. Guided wave radar level transmitters, on the other hand, are excellent for situations where there is foam, vapor, or turbulence in the tank.

The choice of a radar level transmitter for any industrial application depends on several factors, such as tank shape, material being measured, and the process temperatures involved. Selecting the right device for the specific application ensures that the quality of the level measurement data collected is accurate.

Application Considerations for Using a Radar-Level Transmitter

When it comes to level measurement, a radar level transmitter is a popular choice due to its reliability and accuracy. However, there are important application considerations to keep in mind when using one.

First and foremost, it’s crucial to determine the appropriate frequency for the type of material being measured. Additionally, the mounting location and orientation of the radar-level transmitter should be carefully selected to ensure optimal performance.

Finally, it’s important to select the appropriate type of antenna and sealing material to prevent any interference or leakage. By taking these factors into account, you can ensure that your radar-level transmitter is operating effectively and efficiently.

Troubleshooting Common Issues with Radar Level Transmitters

Radar level transmitters are indispensable tools in various industries, providing accurate and reliable level measurements of liquids, slurries, and solids. However, even the most advanced radar-level transmitters are not immune to problems, which can affect their performance and accuracy.

Common issues range from improper installation to signal interference to incorrect calibration. When faced with these issues, it is essential to troubleshoot them as soon as possible to avoid production downtime, safety hazards, and costly repairs.

Effective troubleshooting requires thorough knowledge of the technology and expertise in identifying the root cause of the problem. With the right approach and tools, and by implementing best practices, it is possible to minimize the impact of issues and ensure the optimal performance of radar-level transmitters.

All in all, radar level transmitters provide a reliable and accurate way to measure the liquid level of process vessels. By understanding the advantages and limitations of using a radar-level transmitter, you can ensure its use is successful in your particular application context.