Fluid power technology, the science of harnessing the force of hydraulic and pneumatic systems, is revolutionizing the way we power machines and equipment. By utilizing the power of liquids and gases, these systems provide an efficient and reliable means of transmitting force and motion.

Hydraulic systems, which use pressurized fluids, are known for their immense strength and precision. They are commonly found in heavy machinery, such as construction equipment and industrial presses, where immense force is required. On the other hand, pneumatic systems, which use compressed air or gas, are lighter and more flexible, making them ideal for applications that require quick and agile movements, such as robotics and automation.

Both hydraulic and pneumatic systems offer numerous advantages, including precise control, high power density, and ease of maintenance. Moreover, ongoing advancements in fluid power technology promise even greater efficiency and sophistication in the future.

In this article, we will explore the inner workings of hydraulic and pneumatic systems, their applications in various industries, and the advantages they offer. So, join us as we delve into the fascinating world of fluid power technology and discover how it is shaping the future of engineering.

Understanding Hydraulic Systems

Understanding hydraulic systems is crucial in harnessing the full power and potential of fluid technology. Hydraulic systems utilize the force of liquid to generate and transmit power. To comprehend their operation, it is essential to grasp the key components of a hydraulic system. These include a reservoir, a pump, valves, actuators, and hydraulic fluid. The reservoir stores the hydraulic fluid, while the pump provides the necessary pressure to move the fluid through the system. Valves control the flow of fluid, allowing it to reach the desired actuators. Actuators, such as cylinders or motors, convert the hydraulic energy into mechanical work. The hydraulic fluid, usually oil, serves as the medium for transmitting power within the system. By understanding how these components work together, one can effectively harness the force and potential of hydraulic systems.

Exploring Pneumatic Systems

Explore pneumatic systems and discover how they can make your life easier and more efficient. Pneumatic systems operate on the principle of using compressed air to transmit and control energy. Compressed air is the key element in these systems, as it can be easily stored and transmitted, making it an ideal power source in various industries. Pneumatic systems are commonly used in manufacturing, construction, and automotive applications, where they power a wide range of tools and equipment. Pneumatic tools, such as impact wrenches, nail guns, and paint sprayers, rely on compressed air to deliver precise and powerful performance. The advantage of pneumatic systems lies in their simplicity, durability, and cost-effectiveness. They offer fast and reliable operation, high power-to-weight ratio, and easy maintenance. With the versatility and efficiency of pneumatic systems, you can enhance your productivity and streamline your work processes.

Applications of Fluid Power Technology

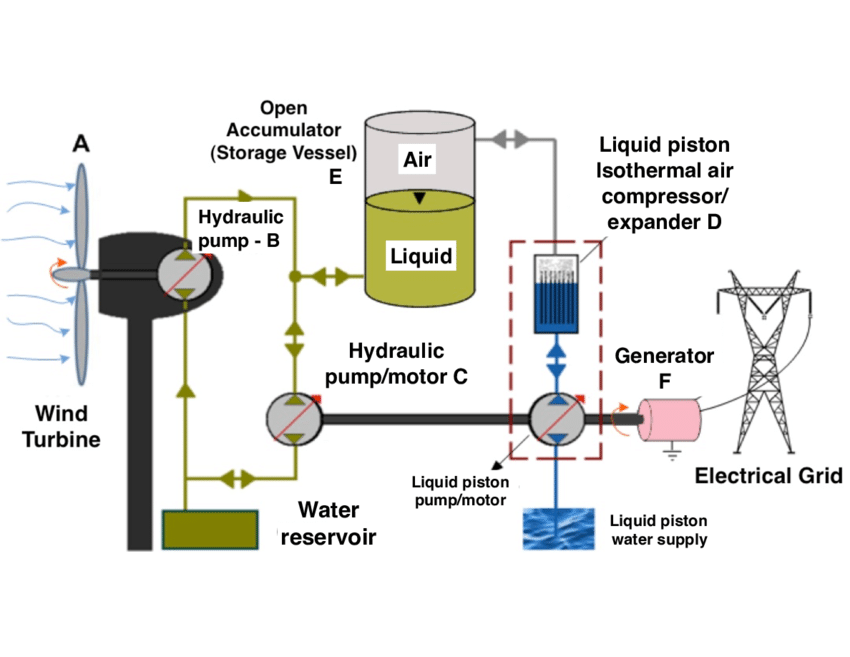

Discover the endless possibilities of using fluid power to revolutionize your industry and unleash your true potential. Industrial automation and renewable energy are two areas where fluid power technology has found extensive applications. In the realm of industrial automation, hydraulic and pneumatic systems are utilized to control and manipulate heavy machinery, enhancing productivity and efficiency. These systems provide precise and reliable force transmission, allowing for smooth and accurate movements. Moreover, fluid power technology plays a crucial role in renewable energy generation. Hydraulic systems are commonly employed in wind turbines to adjust blade angles and optimize energy output. They also enable efficient power transmission and storage in hydroelectric plants. By harnessing the force of hydraulic and pneumatic systems, industries can achieve higher levels of automation and contribute to a more sustainable future.

Advantages of Hydraulic Systems

One of the major advantages of using hydraulic systems is their ability to provide precise and reliable force transmission, resulting in smooth and accurate movements of heavy machinery. Hydraulic systems play a crucial role in the automotive industry, where they are used in various applications such as power steering, braking systems, and suspension systems. By utilizing hydraulic power, these systems can efficiently transmit force and ensure responsive and controlled movements, enhancing the overall performance and safety of vehicles. Additionally, hydraulic systems find extensive use in the construction sector, where they are employed in heavy machinery like cranes, excavators, and bulldozers. The hydraulic technology allows these machines to lift heavy loads, dig deep trenches, and perform other tasks with ease and precision. Thus, the advantages of hydraulic systems make them indispensable in both the automotive and construction industries.

Advantages of Pneumatic Systems

The incredible advantage of pneumatic systems is their ability to deliver powerful bursts of compressed air, leaving you in awe of their sheer force and efficiency. Pneumatic systems consist of various components, including an air compressor, valves, actuators, and air lines. The air compressor pressurizes the air, which is then controlled by the valves to move the actuators. These actuators, such as cylinders or motors, convert the compressed air into mechanical energy, enabling the system to perform various tasks.

One major advantage of pneumatic systems is their low maintenance requirements. Unlike hydraulic systems, which use hydraulic fluid that needs periodic replacement and filtration, pneumatic systems only require clean and dry air. This simplifies maintenance and reduces costs. Additionally, pneumatic systems are highly reliable, as they are less prone to leakage and contamination. The absence of fluid also makes pneumatic systems more suitable for applications in industries where cleanliness is crucial, such as food processing or pharmaceuticals. Overall, pneumatic systems offer a highly efficient and reliable solution for harnessing the force of compressed air.

Future Innovations in Fluid Power Technology

Now that we have explored the advantages of pneumatic systems, let’s turn our attention to the future of fluid power technology. Emerging trends in this field are pointing towards exciting innovations that will revolutionize the way we harness hydraulic and pneumatic forces. One of the key areas of focus is the development of smart systems that can adapt to changing conditions in real-time. These systems will be equipped with advanced sensors and control algorithms, enabling them to optimize performance and energy efficiency. Additionally, there is a growing interest in the integration of fluid power technology with other emerging technologies, such as artificial intelligence and internet of things. However, as with any technological advancement, future challenges lie ahead, including the need for standardization, improved safety measures, and the development of sustainable and environmentally friendly solutions.

Conclusion

In conclusion, you have now delved into the realm of fluid power technology and gained a profound understanding of hydraulic and pneumatic systems. Through this exploration, you have grasped the applications, advantages, and future innovations of these remarkable systems. By harnessing the force of fluid power, industries can achieve enhanced efficiency, precision, and reliability in their operations. With ongoing advancements, the fluid power technology is poised to revolutionize various sectors, opening up new possibilities and optimizing performance. Embrace the power of hydraulics and pneumatics, and unlock a world of endless possibilities.