If Damascus steel is unfamiliar to you, now is the moment to learn it! You have probably used, bought, or held Damascus steel at some point in your life, whether you realize it or not. It is because this metal is exceptionally robust and of the highest quality.

However, do you know what Damascus steel is?

What is Damascus Steel?

Damascus steel was the forging process utilized in and around Syria. Forgers used to combine two or more types of metal to produce the watery motifs on the blades of these knives, resulting in a super-strong alloy. Moreover, due to its strength, Damascus steel is one of the most favored for forging blades. It produces lovely knives!

People get drawn to Damascus steel knives because of the wavy or geometrical motifs on their blades.

While we are on the subject of Damascus steel, here are some lesser-known facts to know!

Little known Facts About Damascus Steel

1. Its Fascinating Origin!

Do you know it is not actually from Damascus? However, this does not negate the fact that it has a few ties to the area. This steel is known as Damascus because it got first introduced to Western Europeans in the third and fourth centuries. It was the trading center of Damascus, which is now Syria. Yup, it is that old!

Are you still wondering where did Damascus steel come from in the first place?

Although some historical accounts claim that part of the steel got made in Damascus, it originated from India and the Middle East. However, we know that Asia and the Middle East are the most likely sources of this unique mineral!

2. The Rich History of Damascus Steel!

Damascus knives have a long and illustrious history dating back millennia. It was created for the first time 2000 years ago and has got widely chronicled throughout history. It is known as old steel!

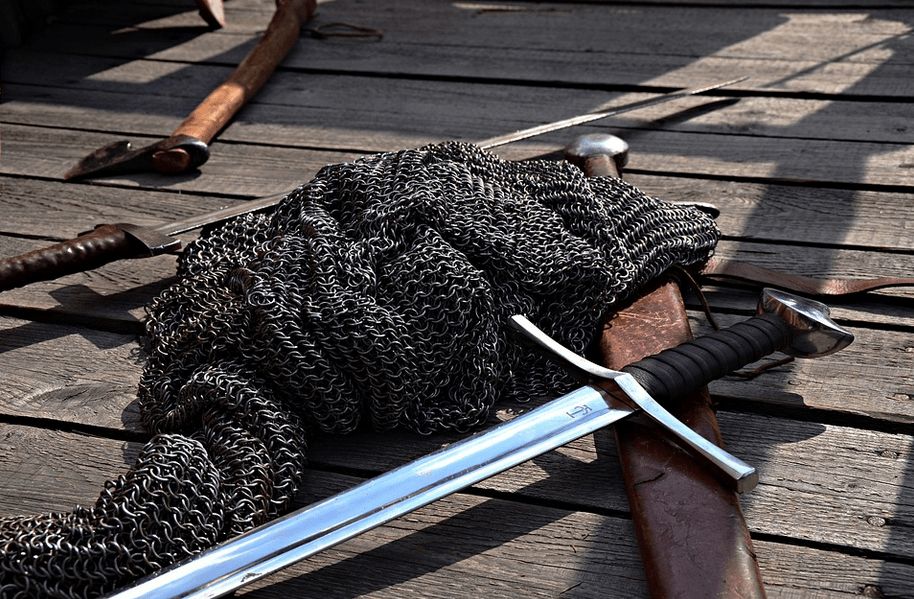

Did you know it owned the weapons industry for hundreds of years?

The Damascus steel got first mentioned during the Christian crusades of the 11th and 12th centuries. Damascus steel rose to prominence throughout these fights.

3. The Special Variety

Have you ever heard the term wootz about steel? It refers to cast Damascus Steel, a labor-intensive product made by melting iron and steel particles with charcoal in a reducing atmosphere. In simple words, it means that oxygen gets reduced or eliminated!

As a result, the metal absorbs carbon from the charcoal and is then progressively cooled. As a result, a noticeable crystalline structure emerges. The material lost its typical wavy appearance when forged into the desired shape (like a sword back in the day). However, the trade-off is a super-strong, high-quality product.

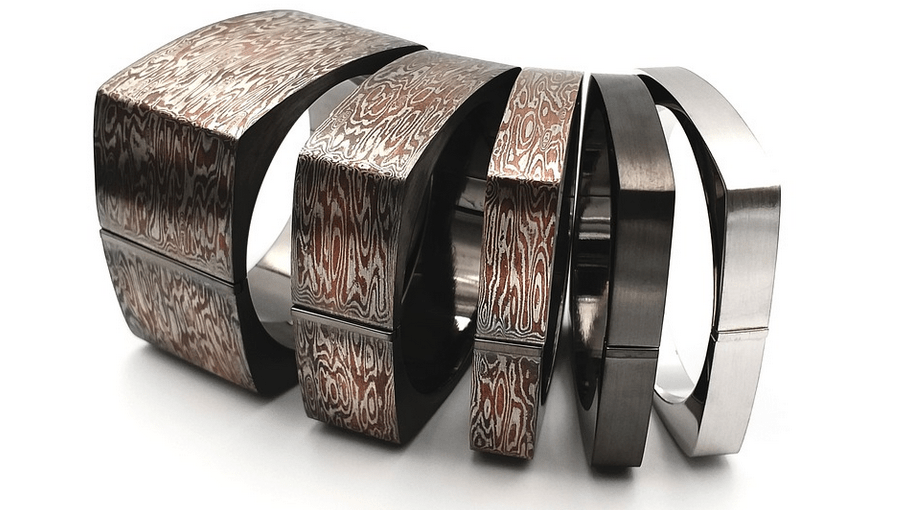

3. The Unique Design

The gorgeous, characteristic design that runs the length of the blade is what makes Damask knives so appealing. Not only the Damascus steel but also the manufacturing process contribute to the dimpled, watery design. Although the metal we use now is not precisely Damascus steel, it is still billet welded, which gives it the multi-patterned pattern seen in fine damask knives of our time.

Billet welding is a technique for fusing a range of steel and iron alloys by first welding them together and then folding the total mass many times, resulting in sandwiched layers of alloys of various colors.

Moreover, you can change the welding process to create different designs.

4. Its Knives and Swords Are Extremely Sharp!

The durability of Damascus blades’ edges is one of the reasons why they are considered investments in the knife business. Damascus blades require substantially less honing than typical production-grade blades. Not to suggest they do not require sharpening, but you will find you sharpen a Damascus blade far less frequently than the rest of your collection. Furthermore, the existence of various steel alloys results in a micro-serration of the edge.

It allows Damascus steel to do slicing or sawing activities. Some folks are concerned about Damascus blades rusting. It depends on the type of steel used in the blade’s construction. The majority of current knives created with this traditional technology are stainless steel and will not rust. Make sure to polish the knives and swords if they got manufactured out of high carbon steel!

5. Damascus Steel Is Very Strong!

Damascus blades are not only sharp (and will stay sharp), but they are also exceedingly robust. Carbon nanotubes exist formed in the steel as a result of the procedure.

The casting of more metals allows it to have incredible strength. Impurities are added to a batch of steel to make either a brittle or malleable blade. Damascus steel is not as robust as some other current metal alloys. It is still capable of performing most duties!

6. It Is flexible too!

Damascus steel has the advantage of being both strong and flexible. Damascus steel is the ideal alloy for making powerful and unbreakable swords, knives, and other bladed weapons because of its unique combination.

7. It May Not Be Real

Real Damascus steel commands a premium due to its time-consuming forging process. It is also because of its high quality and aesthetic appeal. However, not all wavy knife blades exist made of Damascus steel. When purchasing a reported Damascus steel product, be sure to check the source. This metal is commonly used today for kitchen knives and wedding bands!

Bottom line

Damascus steel is well-known steel! However, people still lack information and facts regarding it. The article mentions eight facts about it in a detailed description. It discusses its origin, design, and variety!

We recommend checking out what a neck knife is?